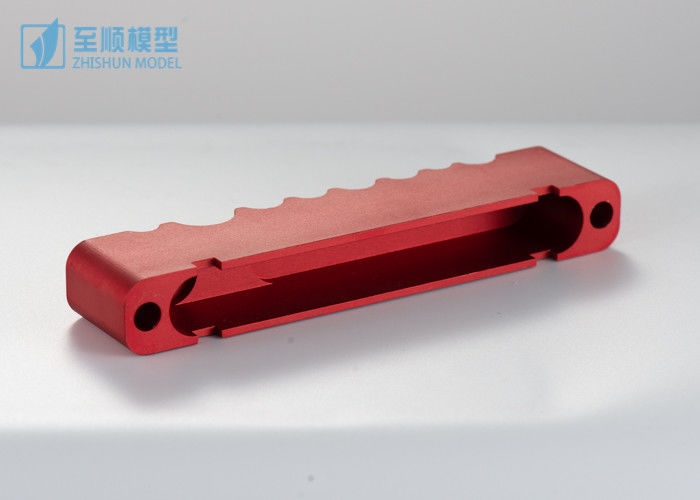

High Strength Rapid Prototyping Plastic , Durable SLS 3D Printing Process

Quick Details:

- CNC Machining or Not:Not CNC Machining

- Micro Machining or Not: Not Micro Machining

- Name:White ABS 3D Printing Rapid Prototype SLA/SLS Teachnical parts

- Type:Laser Machining, Other Machining Services, Rapid Prototyping

- Place of orign:DongGuan,China (Mainland)

- Meterial:ABS

- Color:Color Available

- Material Capabilities:Aluminum,Stainless Steel,Other

- Process:3D printing

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power source to sinter powdered material (typically nylon/polyamide), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. It is similar to direct metal laser sintering (DMLS); the two are instantiations of the same concept but differ in technical details. Selective laser melting (SLM) uses a comparable concept, but in SLM the material is fully melted rather than sintered,allowing different properties (crystal structure, porosity, and so on). SLS (as well as the other mentioned AM techniques) is a relatively new technology that so far has mainly been used for rapid prototyping and for low-volume production of component parts. Production roles are expanding as the commercialization of AM technology improves.

Company capability:

1. CNC prototyping

we can process prototypes in a range of block material with max dimension up to 1800*1100*650mm,we process the work piece by cutting the unwanted material from cnc equipment ,normal lead time of cnc prototyping is 4-5 days. High surface and the complex shape parts are fit for this processing way .our cnc machines can typically machine components on home appliance, medical device, car parts and electronic products with high quality.

2. SLA/SLS rapid prototype

SLS/SLA rapid prototype fit to make the complicated and small parts.machines we brought in are capable of producing detailed parts with good surfacefinish and with high tolerance. It was applied when a low number of prototypes is needed. But for larger parts, we suggest using cnc machining way which

has great advantage when needs larger parts.

3. silicon mold

Silicon molded is ideal for building 10 to 100 pieces our of broad range of polyurethanes and other polymers. The textures, color and profiles of the intended items will be reproduced to be loyal of the master model. Usually 4-5 days is enough for delivering .

4. material of prototype

ABS, polycarbonate (PC), delrin(POM), PP, PA, PVC, PBT, PE, acrylic (PMMA), aluminum(different grade), PA+30GF, PU(for silicon mold parts),Sheet metal, copper, stainless steel, brass, etc.

5. surface treatment for prototype

Painting (spraying), anodizing, electroplating, brushed, sandblasting, printing, transparent, translucent, rubber, paint, plating and etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!