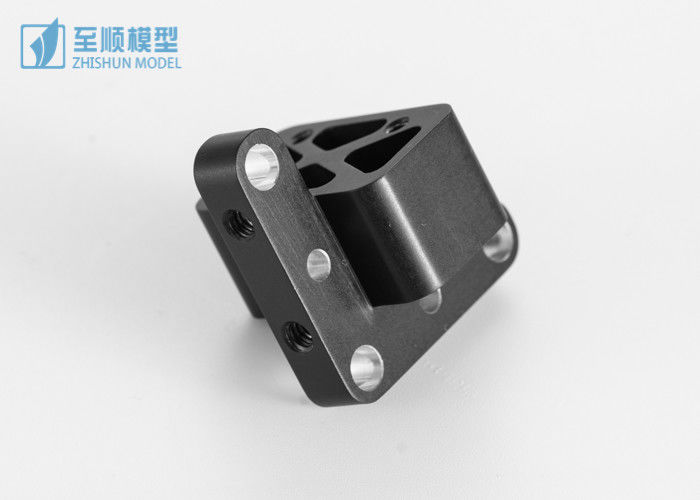

Rapid Hardware Plastic CNC Prototype For Car / Bicycle / Scooter Parts

Services including: Rapid prototyping, 3d printing service, cnc machining and sla prototyping

1.Part design analysis

2.Supplying 3d printing service for rapid prototyping, as well as CNC machining for rapid prototyping

3.Prototype materials can be pc, abs, pmma, aluminum, etc.

4.Normally it will take about 5-15days to make prototypes depends on part design.

What is CNC machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing technology: parts are created by removing material from a solid block (called the blank or the workpiece) using a variety of cutting tools.

This is a fundamentally different way of manufacturing compared to additive (3D printing) or formative (Injection Molding) technologies. The material removal mechanisms have significant implications on the benefits, limitations and design restrictions of CNC. More on this below.

CNC machining is a digital manufacturing technology: it produces high-accuracy parts with excellent physical properties directly from a CAD file. Due to the high level of automation, CNC is price-competitive for both one-off custom parts and medium-volume productions.

Almost every material can be CNC machined. The most common examples include metals (aluminum and steel alloys, brass etc) and plastics (ABS, Delrin, Nylon etc). Foam, composites and wood can also be machined.

The basic CNC process can be broken down into 3 steps. The engineer first designs the CAD model of the part. The machinist then turns the CAD file into a CNC program (G-code) and sets up the machine. Finally, the CNC system executes all machining operations with little supervision, removing material and creating the part.

Advantage:

1. Good quality,high accuracy up to 0.01mm.

2. Can process parts with complex structures.

3. A range of materials available.

4. Easier to control quality for small batch production,also can save cost.

5. No need mold,can make the ideal product.

Quick Detail:

| Product Type |

Rapid Prototyping |

| Material |

PMMA |

| Tolerance |

as per customers' requirement. |

| Product Dimension |

Various size are available |

| Product Shape |

Customized |

| Processing Type |

CNC Machining |

| Surface Treatment available |

polishing,sandblasting,painting,anodizing,electroplating,etc. |

| Design |

We use the most advanced mould design software Auto CAD, Pro/E, (IGS, STP, X-T) |

| Packaging |

Standard export packing:

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

4. Deliver out by UPS, DHL,FEDEX

Or according to customers' requirement.

|

| Shipment |

3-10 working days after received your payment,or depend on customers' desire. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!